Best Business Quality Assurance

Precision Steel stocks 301 stainless steel in the, 1/4 hard, 1/2 hard, 3/4 hard, full hard, and extra hard tempers Stainless steel 301 is known for its high strength and excellent corrosion resistance. Alloy 301 is non-magnetic when annealed however it has the ability to be modified along with its other properties. Because of the versatility of this grade of stainless steel, it makes 301 stainless steel the ideal material for a multitude of applications. 301 Stainless Steel is also known as International Grade.

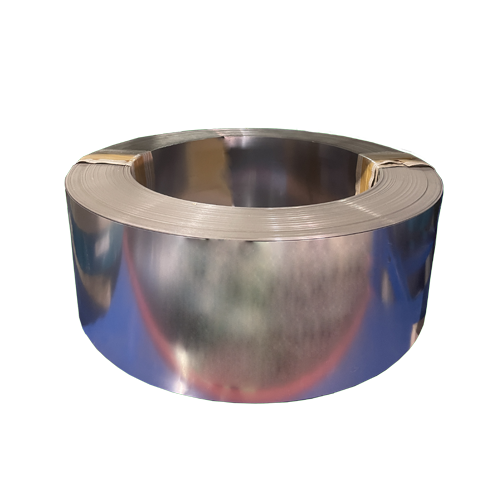

430Stainless Steel Coil &Sheet

430 stainless steel coil and sheet is a ferritic, low carbon stainless steel. It has good corrosion resistance in a mildly corrosive environment and good oxidation resistance at elevated temperatures. 430 has limited weldability and edge welds are not recommended. 430 has excellent polishing characteristics and is used in a variety of decorative applications.

409 Stainless Steel Coil & Sheet

409 stainless steel whose mechanical properties highly outshine its physical appearance than 409 stainless steel is your perfect match. 409 Stainless is ideally used in scenarios where a need for oxidation or even corrosion protection is wanted. As a titanium stabilized ferritic stainless steel, 409 is most commonly used in automotive exhaust systems where the environment can be quite taxing on the lifetime of the steel.

409 is the perfect grade stainless steel to be used in automotive applications where visual appeal is not a top priority. For this reason and for its durability to gas corrosion, 409 is most commonly used in truck exhaust systems, agricultural equipment, and heat and gas turbine exhaust silencers

| Grade | Chemical Composition | ||||||

|---|---|---|---|---|---|---|---|

| JIS | C | Si | Mn | P | S | Ni | Cr |

| 301 | 0.15 Max | 1.0 Max | 2.0 Max | 0.045 Max | 0.030 Max | 6.0~8.0 | 16~18 |

| 304 | 0.08 Max | 1.0 Max | 2.0 Max | 0.045 Max | 0.030 Max | 8.0~10 | 18~20 |

| 430 | 0.12 Max | 0.75 Max | 1.0 Max | 0.040 Max | 0.030 Max | 0.6 Max | 16~18 |

| 409 | 0.03 Max | 1.0 Max | 1.0 Max | 0.040 Max | 0.030 Max | 0.6 Max | 10~12 |